Views: 0 Author: Silver Rocket Publish Time: 2025-11-21 Origin: Site

Resin-coated aluminum powder is gaining widespread adoption across various industries, particularly in the coatings sector where it is highly favored for its enhanced durability, weather resistance, and exceptional metallic effects.This article explains what it is, how it works, and why it matters.

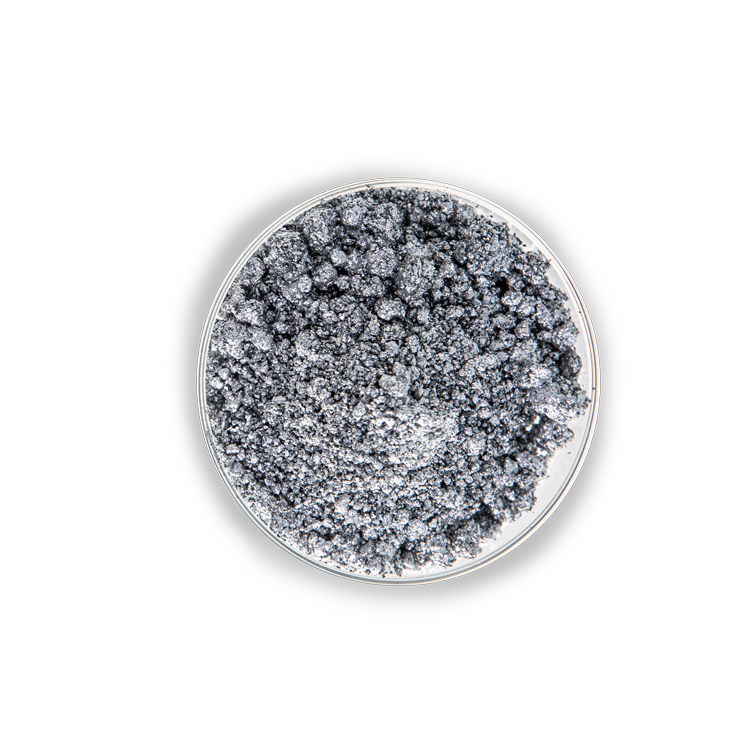

Resin coated aluminum paste is a specialized form of aluminium paste where each aluminum flake is encapsulated with a resin film.

This coating creates a dense protective layer, offering:

Strong chemical resistance

Excellent adhesion

Improved compatibility with coating resins

Enhanced electrical insulation

Smooth and flat coating appearance

This technology is widely used in coil coatings, fluorocarbon exterior coatings, and other applications requiring resistance to corrosion and environmental stress.

The resin layer enhances the traditional performance of aluminium paste by improving stability and protecting the metallic flakes.

The resin film allows excellent compatibility with most coating resins and solvents.

This results in a uniform metallic effect and a smoother film surface.

Resin-coated flakes resist:

Acid and alkali corrosion

Moisture

Oxidation

Outdoor UV exposure

This makes them ideal for outdoor and industrial coatings.

The coating remains firmly bonded even under complex working environments.

Its insulation properties also benefit electronic and industrial applications.

Below is the updated performance parameter table

It reflects key technical data from Silver Rocket’s production standards.

| Grade | Non-Volatile Content (±2%) | Solvent | Screen Analysis (45 µm<%) | Average Particle Size (µm) | Surface Coated | Particle Shape | Leafing / Non-leafing |

|---|---|---|---|---|---|---|---|

| ZRC-06S | 55% | Mineral oil | 99.5 | 6 | Acrylic resin | Silver dollar | Non-leafing |

| ZRC-13S | 55% | 99.5 | 13 | ||||

| ZRC-20S | 55% | 99.5 | 20 |

This data is based on Silver Rocket’s production specifications and industrial application testing.

Using resin coated aluminum paste provides several meaningful industrial benefits:

The resin layer isolates aluminum flakes from chemical attack.

Reduced reaction between aluminum and water/solvents.

Especially important for high-end automotive refinish and coil coating markets.

Lower risk of gas generation and oxidation in water-based or acidic systems.

Resin coated aluminum paste is widely used in:

High-grade OEM coatings

Automotive refinish coatings

Coil coatings

Fluorocarbon exterior wall coatings

Plastic coatings

Corrosion-resistant industrial coatings

Insulation coatings

Its stability and non-leafing properties are especially valued in high-performance coating formulations.

Yes. The resin layer greatly improves water resistance, making it safer and more stable in water-based systems.

Leafing: Aluminum flakes float to the surface, creating a mirror-like effect.

Non-leafing: Flakes distribute evenly throughout the film, offering better protection and uniform color.

All grades listed above are non-leafing, suitable for protective coatings.

It resists corrosion, prevents oxidation, improves adhesion, and provides better long-term durability.

Resin coated aluminum paste provides a modern solution for industries needing robust performance, chemical resistance, and smooth metallic brilliance. As an advanced aluminium paste, it continues to gain popularity across automotive, industrial, and architectural coatings.

To request samples or technical data, contact Silver Rocket Metallic Pigment Co., Ltd.

Website: https://www.silverocket.com/

Email: info@silverocket.com

+86-531-83261860

+86-15854170788

Sangyuan industrial park,Zhangqiu City,Shandong Province,250203, China.