Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

Master the use of aluminum paste with our expert guide. Learn the difference between leafing & non-leafing types, proper storage, dispersion techniques, and solving common application issues.

The Ultimate Guide to Aluminum Paste: From Properties to Application Mastery

Aluminum paste is a fundamental ingredient for creating stunning metallic effects in industrial coatings, inks, and plastics. However, achieving a perfect, consistent finish requires a deep understanding of its properties and correct handling.

Section 1: Understanding Aluminum Paste Properties and Types

Aluminum paste is composed of finely ground aluminum flakes dispersed in a solvent and additive system. The quality of the paste is defined by the smoothness, flatness, and uniform size distribution of these flakes, which are responsible for its exceptional light reflection and brilliant metallic luster. When combined with transparent color pigments, it can create sophisticated "angle-dependent color effects."

A critical distinction lies between two main types:

Leafing Aluminum Paste: Treated with stearic acid, the flakes float to the surface of the coating film as it dries. This creates a continuous, mirror-like reflective layer, offering a chrome-plated appearance. This type provides excellent impermeability but can present challenges for intercoat adhesion.

Non-Leafing Aluminum Paste: The flakes are wetted by the binder and remain distributed throughout the film. This results in a solid, durable finish with a distinct metallic glow and excellent adhesion for subsequent coats, making it ideal for most automotive and industrial applications.

Section 2: Key Application Industries

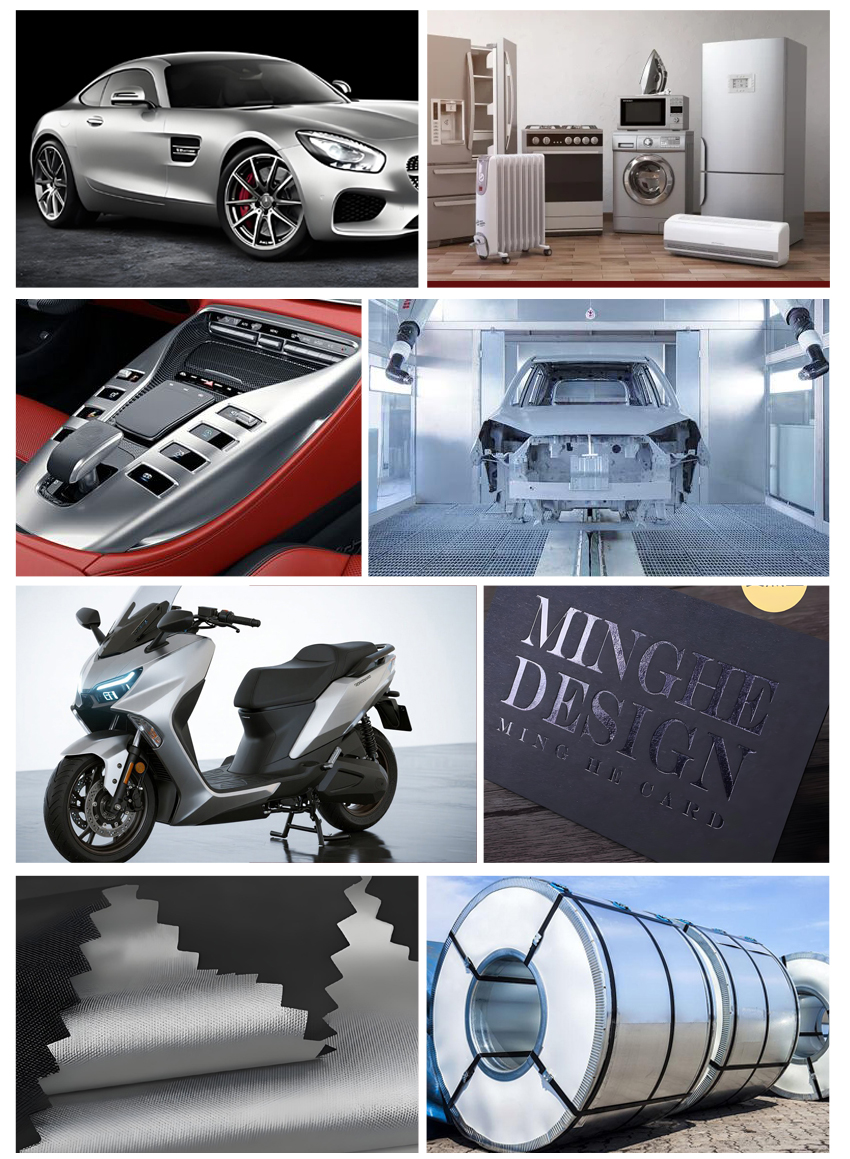

Aluminum paste from Silver Rocket is engineered to perform in demanding environments across various sectors:

Industrial and Protective Coatings: For storage tanks, shipping vessels, and machinery, providing corrosion resistance and a bright, reflective finish.

Plastics and Inks: Delivering brilliant metallic effects to plastic components and premium packaging inks, requiring high stability and fineness.

Automotive Paints: Creating the deep, sparkling metallic effects that define modern vehicle finishes.

Section 3: Essential Storage and Handling Protocols

Proper storage is crucial to maintaining the performance and shelf life of aluminum paste.

Storage Conditions: Store in a cool, dry, and well-ventilated area, ideally between 15°C and 40°C (59°F - 104°F). Keep containers tightly sealed to prevent solvent evaporation and moisture absorption.

Transportation: Avoid vigorous shaking and exposure to extreme temperatures during transit.

Usage: After opening, use the paste as soon as possible. If not used completely, reseal the container immediately to preserve quality.

Section 4: Expert Tips for Optimal Application and Problem-Solving

Dispersion and Binder Selection:

Achieving a homogeneous mixture is key. Stir the paste gently into the system. Avoid high-speed mixing, as it can bend, break, and destroy the aluminum flakes, leading to a loss of metallic brilliance and darkening of the finish. Always ensure compatibility between the aluminum paste and your chosen resins, solvents, and additives.

Solving Common Problems:

Darkening or Blackening: Often caused by chemical reaction with a high-pH system (especially in water-based coatings), use of strong polar solvents, or excessive shear during dispersion.

Solution: Check the pH of your system, use recommended solvents, and employ low-shear mixing techniques.

Poor Gloss or Haze: Usually a result of inadequate dispersion or flake damage.

Solution: Ensure proper, gentle stirring and use high-quality pastes, which are designed for easy incorporation.

+86-531-83261860

+86-15854170788

Sangyuan industrial park,Zhangqiu City,Shandong Province,250203, China.